Electrical Discharge Machining (EDM)

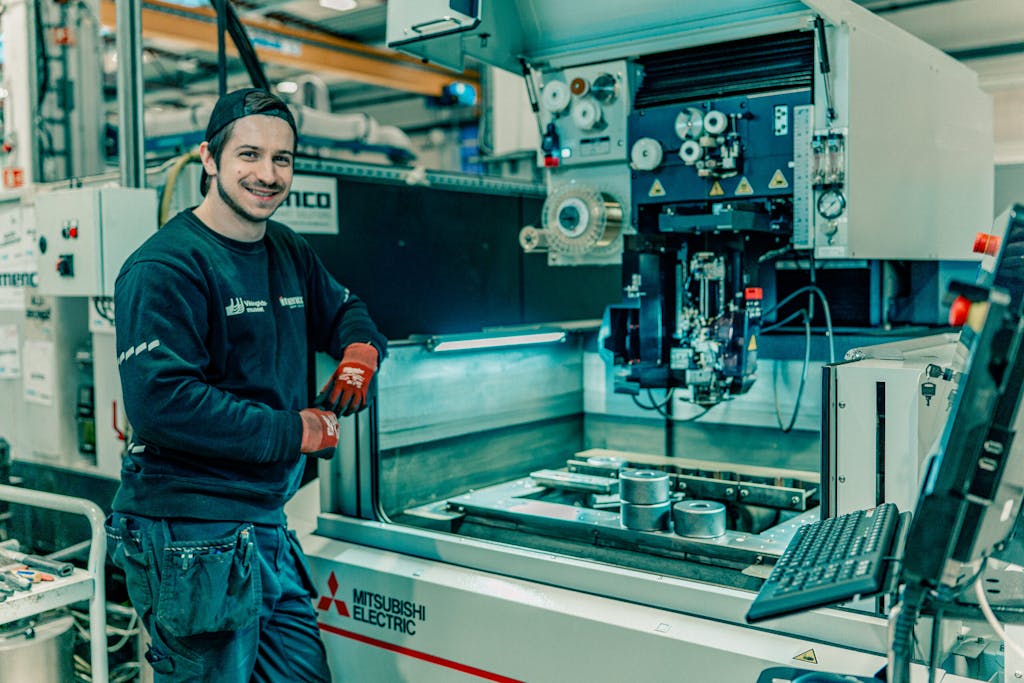

Electrical discharge machining (EDM) is a non-traditional form of precision machining that uses thermal energy instead of mechanical force to remove material from a workpiece.

EDM contains Wire erosion and Spark erosion. Wire erosion is a precision engineering process that involves cutting a workpiece with a strand of wire. Spark erosion, also known as sinker EDM or Die-sinking EDM, is a process to shape and form metal parts with high precision.

Wire erosion

The production method for extreme accuracy

Wire erosion is a form of electrical discharge machining (EDM) that makes it possible to machine hard materials with an accuracy that few other methods can match.

Wire erosion uses a thin, electrically conductive wire – preferably in the form of a Ø0.25mm coated brass wire – as a tool for cutting or shaping metal. The wire moves through the workpiece without touching it directly.

Spark erosion

The production method for complex shapes

Spark erosion is often used when there is a need to create very complex, precise shapes, preferably in hard materials such as iconell, duplex, superduplex or other steel and metal alloys.

Flexibility in design – The electrode can be precisely shaped to the desired geometry, allowing the creation of highly intricate details, deep cavities and complex structures that would be difficult with more traditional machining methods.

Reliability – From planning to the part being fully machined, the entire process is characterized by a systematic approach where nothing is left to chance. This combination of technology, experience and accuracy ensures that the end result is reliable and durable.

Optimum for advanced solutions – When the accuracy, shape of the part or the type of material mean that other machining methods are not sufficient, deep-sinking can be the solution – both in terms of quality and precision.

EDM News and Case Studies

Solutions for EDM

Contact

Martin Tønnessen

Other Solutions for Fabrication

Workshop and facilities Voll. The floor area measures 6200 square meters and the building contains, among other things, CNC- machinery, a powerful and large assembly hall, pressure testing pool for testing of underwater equipment, the pool measures 7m x 5m x 5m. 5 smaller test-pits for pressure- testing up to 1.750 bars Several overhead cranes [...]

Industry 4.0. Industry 4.0 is wholly concerned with connecting people, systems, and equipment to communicate, monitor, and inform. This enables manufacturers to develop a better understanding of their operation, and support use cases that drive process optimization, predictive maintenance, automation, and more. Imenco focus on GibbsCAM, Vericut and WinTool for programing, simulation and pre quality control [...]

Welding. Structural and clad welding services. A number of WPQs and WPS to perform assignments in construction welding, repair welding and cladding.Horizontal Cladding Rig - cladding up to 20 meters length.Vertical Cladding Rig - various opportunities like seal areas, ring grooves, valve seats and internal bores.Butt welding with Narrow Gap.Our welding services are certified according [...]

QC - Quality Control. CMM - Coordinate Measuring Machine. With our Coordinate Measuring Machine we perform quality control of our products to ensure that we are in line with requested requirements. We also perform quality control for clients who produce their own components. We have 2 Zeiss measuring machines: Maximum capacity L4,2m x W2m x [...]

Precision and quality. We provide machining services where the focus is precision, delivery capability at competitive prices and close follow-up to customer. 01/07 Market-leading qualityand workmanship. Decades of deliveries of Advanced Machining services have provided us with in-depth expertise and experience in all types of machining that enable us to offer machining of market-leading quality [...]

A modern production facilitywith large capacity. The production capacity at Imenco Voll ranges from serial production to prototype manufacturing of equipment or assembly. We handle all materials from ordinary steel to exotic materials such as titanium or Inconel. Our production ranges from serial production to prototype manufacturing of equipment or assembly. We at Imenco help [...]

Millturn. MachineMax turn diaMax turn lengthMazak IG 670H II-LB-U9806000Mazak IG-650H II-LB9254000Mazak IG-500H II-LB5503122Mazak IG-500H II5503122Okuma Multus U40006502000Mazak IG-I-4004001500Mazak IG-400Y4001500Mazak IG-200-VI2151045Mazak IG-200-III2151045 Turning with rotation tool. MachineMax turn diaMax turn lengthMazak Nexus 350-II MY4201400Mazak QTS 350M3201250Okuma LU153401060Okuma Genos L300-EM3001060Mazak QTS 200 M1572000Mazak Nexus 250-II MY210600 Turning without rotation tool. MachineMax turn diaMax turn lengthWeiler3152000 Mill. MachineX-axisY-axisZ-axisMazak [...]